|

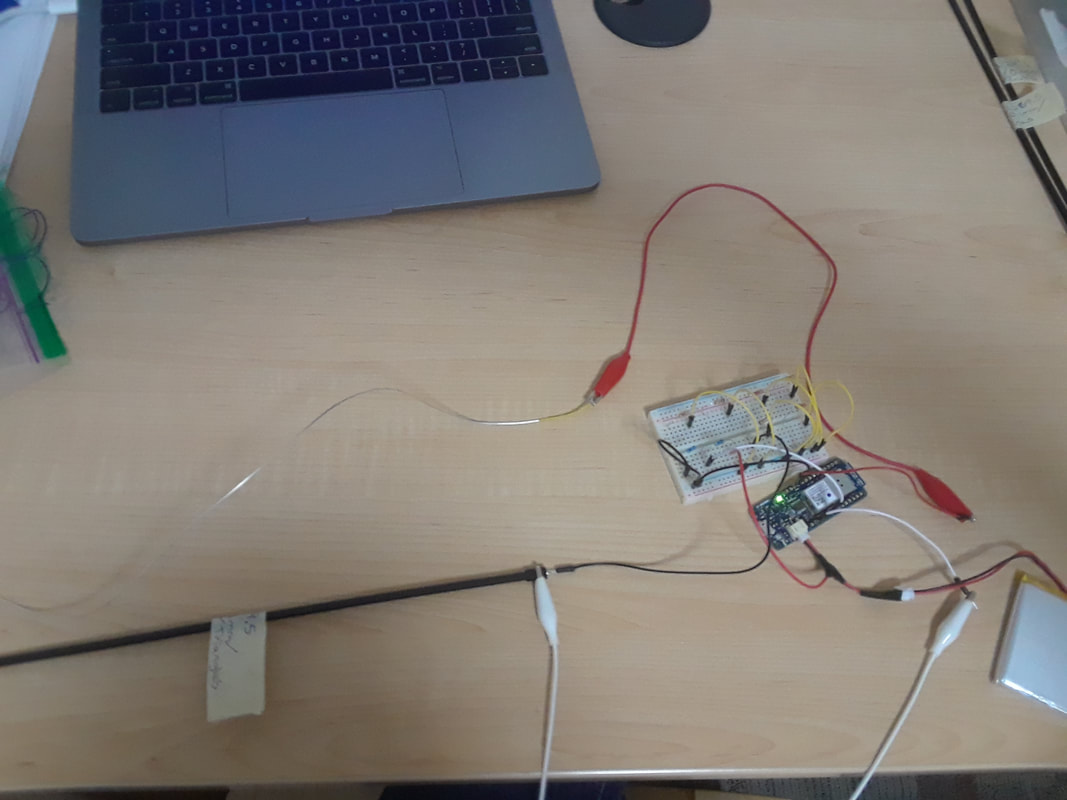

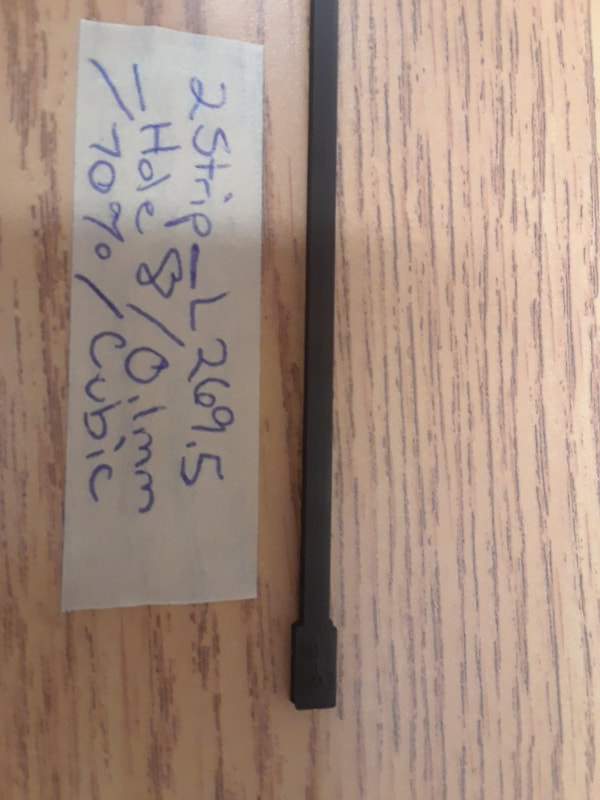

I did a lot of testing with strip file 2Strip_L269.5_Hole8.stl with the Arduino. It was printed with a layer height of 0.1mm and triangle pattern. I compared The Dominant strings and the Evah Pirazzi’s, and combined them with a series of different resistors.

G Dom The voltmeter reading is consistent with the string testing in that everything is much more stable. I am actually estimating more confident readings with this than the last test strip that I tested with the Arduino. none: 20-85 1k: 105-375 3.3k: 260-720 4.7k: 330-750 10k: 510-850 22k: 710-945 47k: 845-975 G Evah none: 20-85 1k; 108-300 3.3k: 255-685 4.7k: 325-700 10k: 500-840 22k: 705-930 47k: 855-1003 D Dom none: 16-70 1k: 105-245 3.3k: 255-645 4.7k: 330-545 10k: 518-805 22k: 705-915 47k: 845-970 D Evah none: 20-105 1k: 110-450 3.3k: 265-640 4.7k: 340-750 10k: 515-840 22k: 715-920 47k: 850-980 A Dom none: 20-50 1k: 108-440 3.3k: 245-630 4.7k: 330-550 10k: 505-840 22k: 705-930 47k: 845-975 A Evah none: 15-50 1k: 95-120 3.3k: 235-490 4.7k: 320-595 10k: 500-740 22k: 685-805 47k: 845-920 E Dom This string fluctuates more than the rest of the strings that come in the dominant pack. 22k must have been a mistake as I was brain dead by the time I got here. none: 15-33 1k: 90-250 3.3k: 215-370 4.7k: 295-550 10k: 380-630 22k: 650-450 47k: 815-885 E Pirastro Gold This one is more stable than the dominant E. none: 18-60 1k: 105-400 3.3k: 250-540 4.7k: 315-765 10k: 500-885 22k: 640-915 47k: 830-985 E Evah none: 15-45 1k: 102-250 3.3k: 205-560 4.7k: 320-660 10k: 480-740 22k; 670-920 47k: 840-940

0 Comments

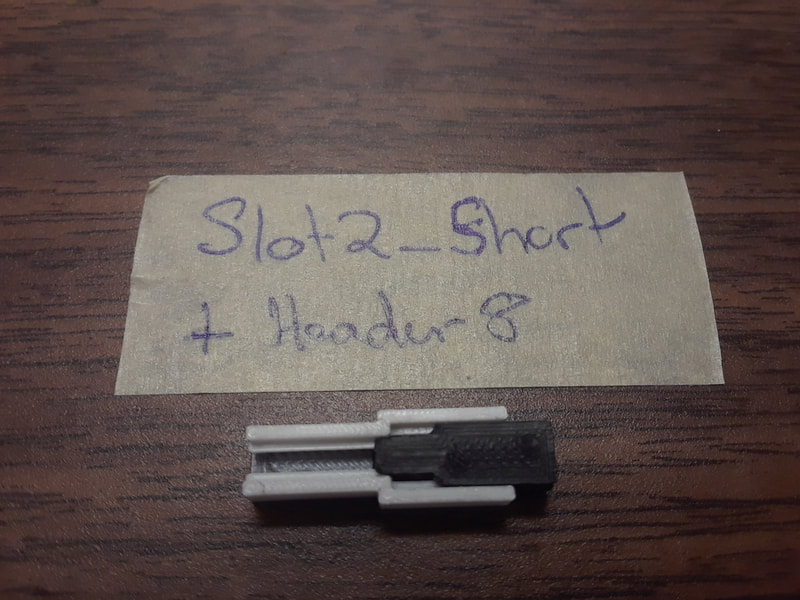

I also discovered that the printer made hole8 perfect with the regular pla, but when I used the conductive pla, the header didn’t quite fit, so I am testing again with the conductive… L.

Files: Hole9.stl, Hole10.stl, Hole9.2.stl.

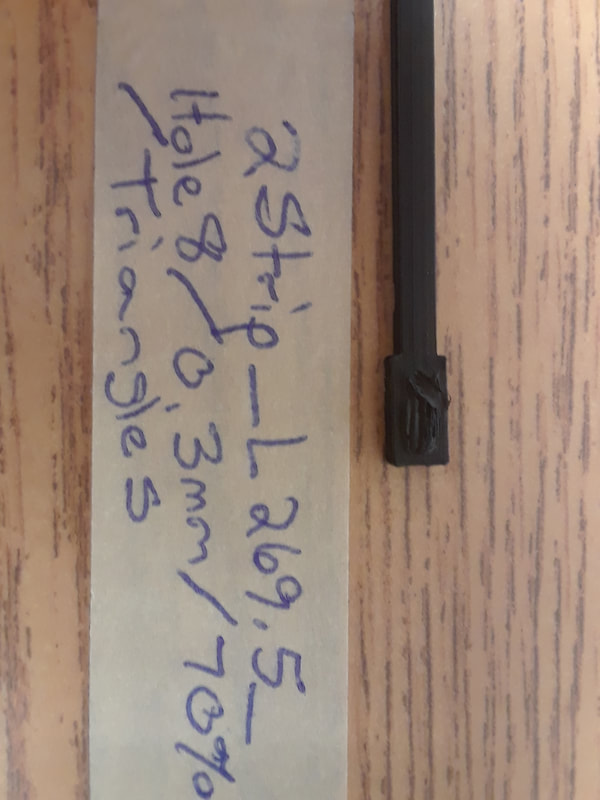

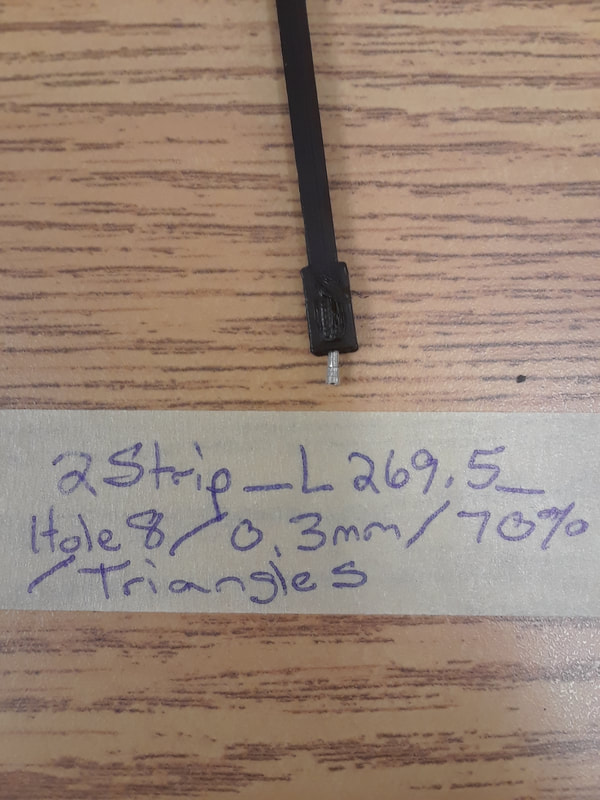

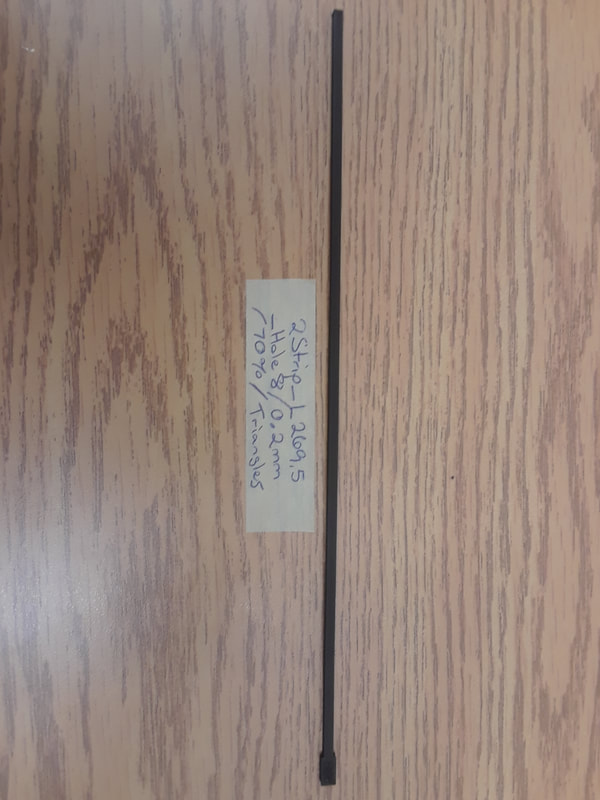

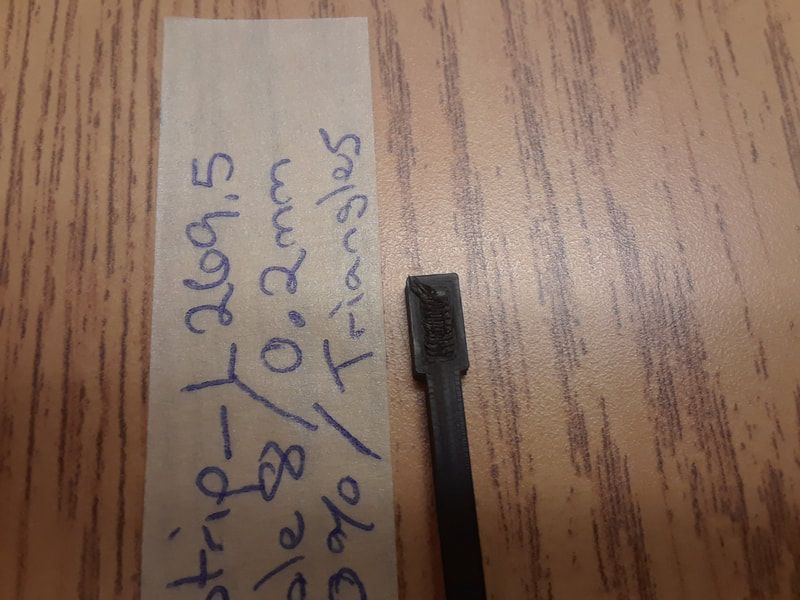

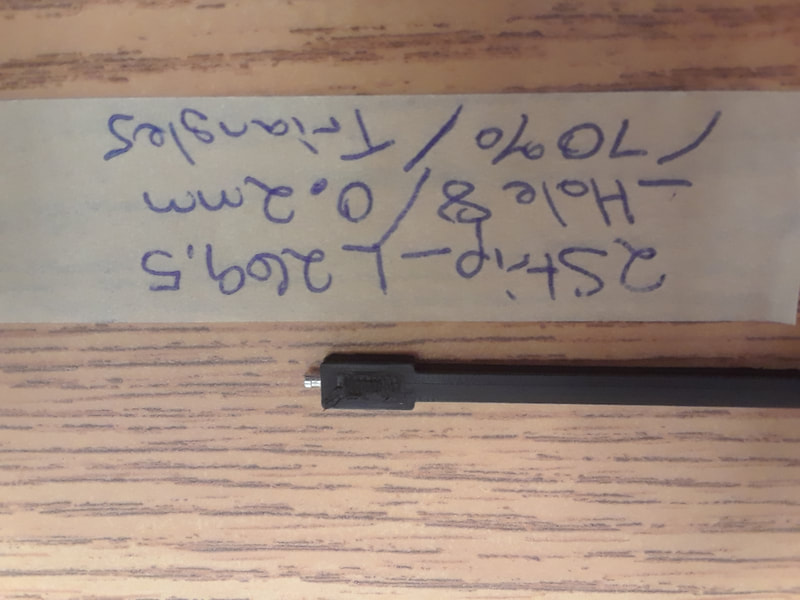

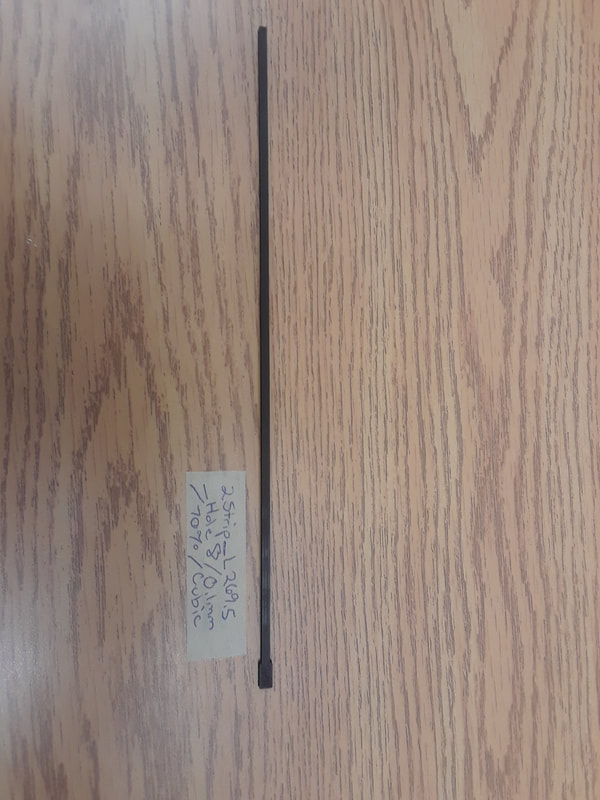

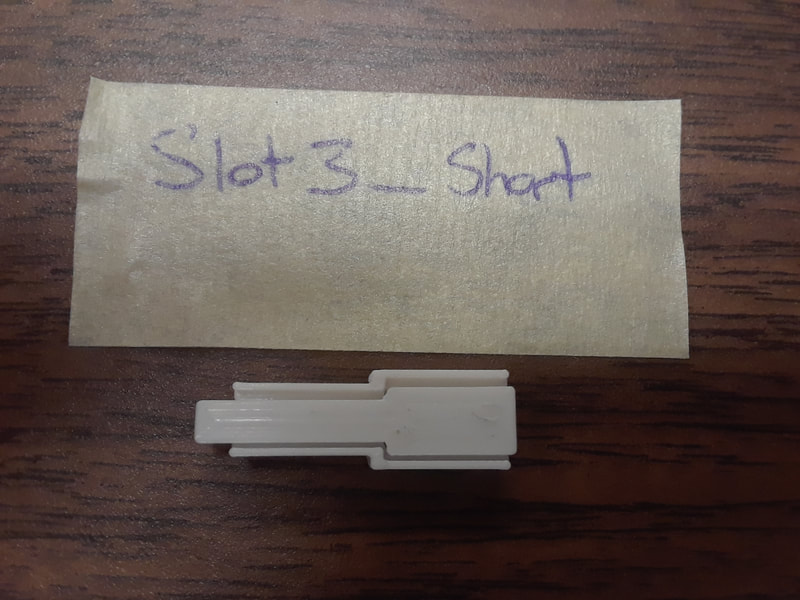

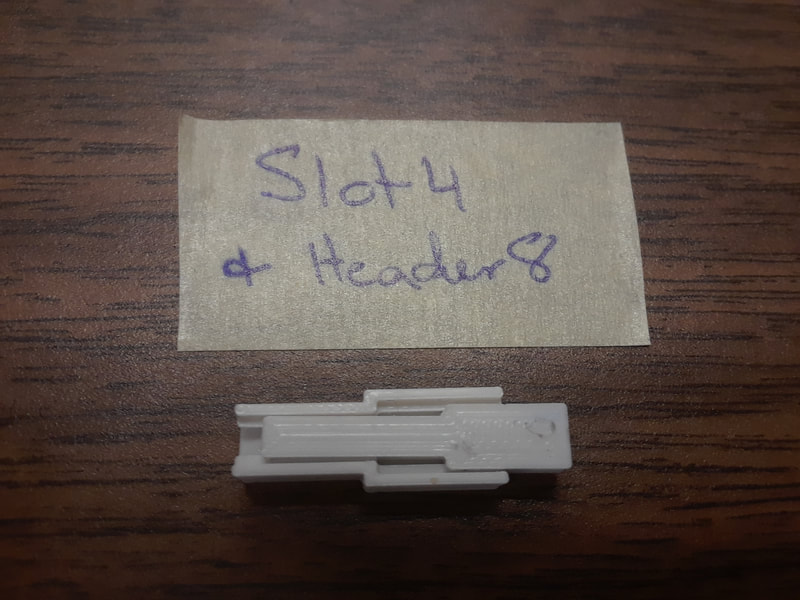

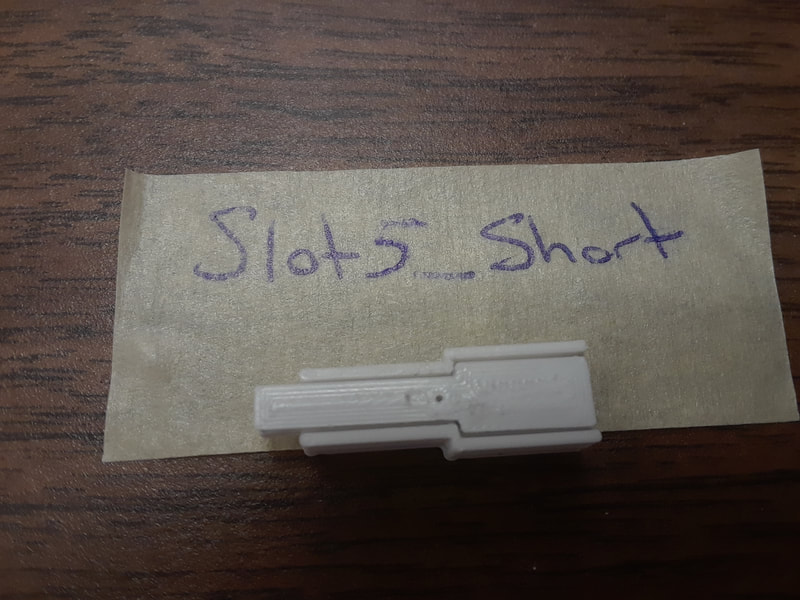

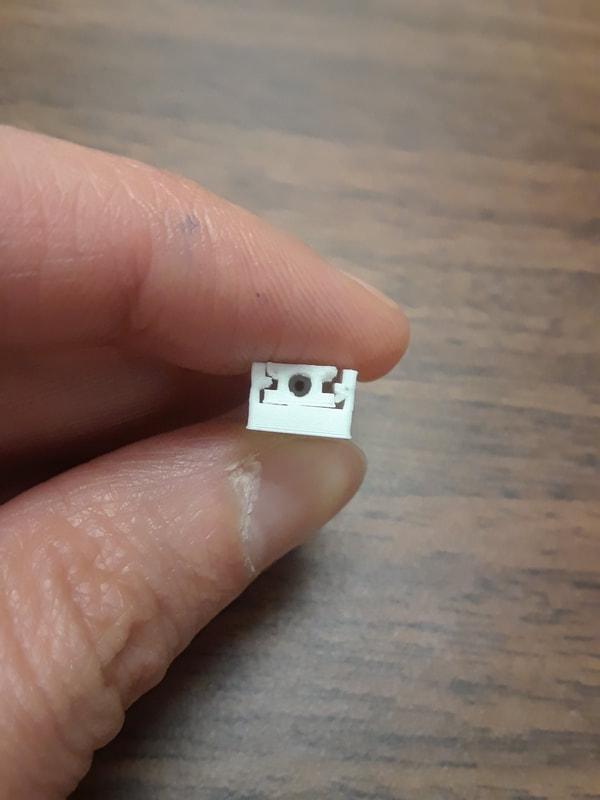

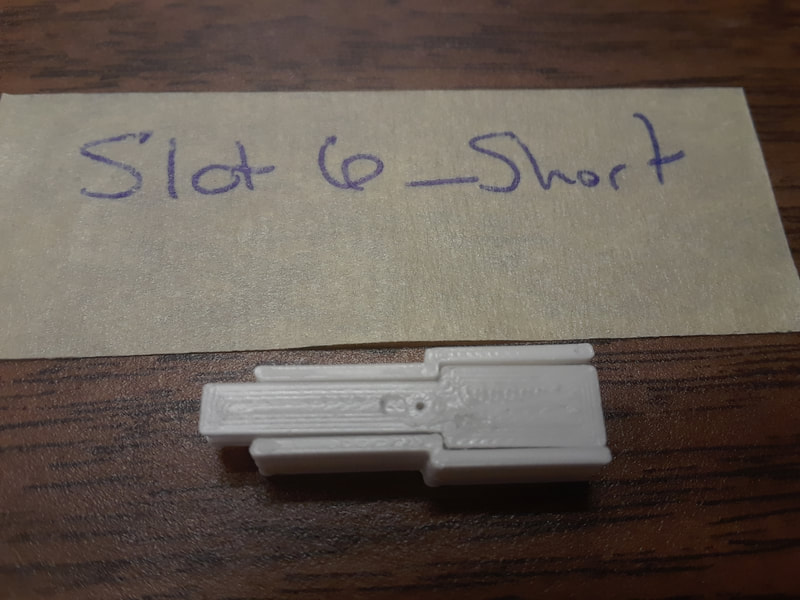

I decided to change up the printer settings to see if that changes the resistance of the same strip file. Infill density was always 70%. I tested different layer height thicknesses and different infill patterns. There was no significant differences with different patterns, but there was with different thicknesses. Test strip file: 2Strip_L269.5_Hole8.stl Strips: Layer Height: 0.1 mm. Infill Pattern: Triangles: Good fit with the test slot7. Good space at the very end to fit the needle. Took 44min to print. The header is not quite fitting in perfectly like it was with the regular PLA. It might have to do with the differences between conductive and regular? It’s not that bad though. I can still work with this. When I tested with the volt meter, the readings are much more stable than the last print that I tested with a volt meter for. When comparing with the other thicknesses, I think the 0.1mm is more stable than the others, but it’s really hard to tell. Multimeter Readings: 20MW : Close: 0 Mid: 0 End: 0.01 2MW : Close: 0.003 Mid: 0.007 End: 0.011 200KW Close: 4.0 Mid: 6.2 End: 11.2 20KW Close: 2.55 Mid: 6.1 End: 11.6 2kW: nothing Layer Height: 0.2mm. Pattern: Triangles. Takes 23 min to print. The top of the header piece is messed up and the header doesn’t fit in the slot. Better than the 0.3 though. Multimeter Readings: 20MW Close: 0 Mid: 0 End: 0 2MW Close: 0.003 Mid: 0.006 End: 0.009 200KW Close: 2.3 Mid: 6 End: 9.8 20KW Close: 3.38 Mid: 6.5 End: 8.66 2kW: 0L Layer Height: 0.3mm. Pattern: Triangles. Takes 16min to print. Much better than the 0.5mm infill. The top of the header piece is messed up and the header doesn’t fit in. This one fluctuates more than the other two. Multimeter Readings 20MW Close: 0 Mid: 0 End: 0 2MW Close: 0.004 Mid: 0.006 End: 0.01 200KW Close: 2.5 Mid: 9.5 End: 0L 20KW Close: 1.27 Mid: 5.8 End: 7.7 2kW: 0L Layer Height: 0.5mm. Pattern: Triangles. Takes 10min to print… don’t know why it’s so much different from the last one. It turned out absolute crap. The header looks messy at the top. I’m not even going to try to fit a header in there. It’s slightly smaller than the edges of slot7, so it is not flush with the top. Harder to get off of the build plate, so the header bent a bit, and won’t bend back. Not functional. Numbers are lower than the thinner thicknesses. The thicker the layer height, the worse the resistance gets. Multimeter Readings: 20MW : Close: 0 Mid: 0 End:0.01 2MW : Close: 0.002 Mid: 0.006 End: 0.02 200KW Close: 3.1 Mid: 4.7 End: 7.0 20KW Close: 1.64 Mid: 4.06 End: 6.82 2kW: 0L I made the test slots short so I could see how they are fitting and not waste filament. I tested the slots with the HeaderHole8.stl file.

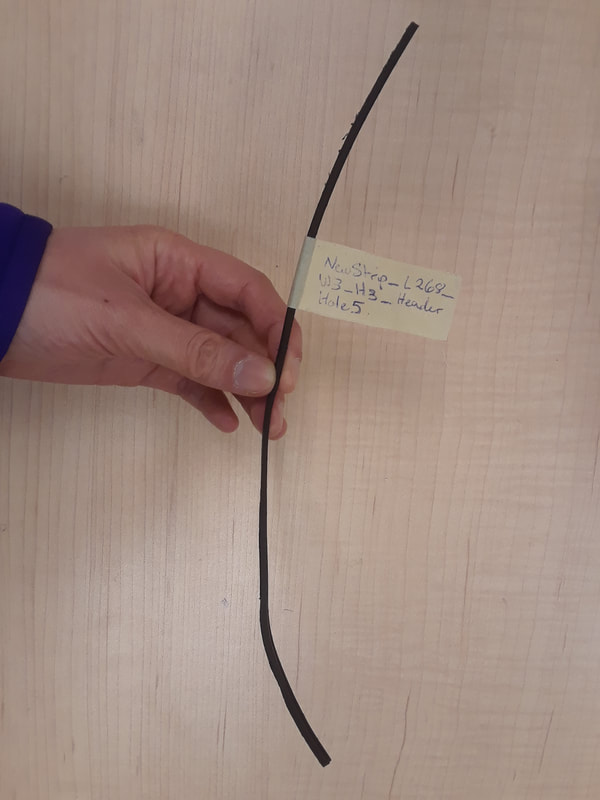

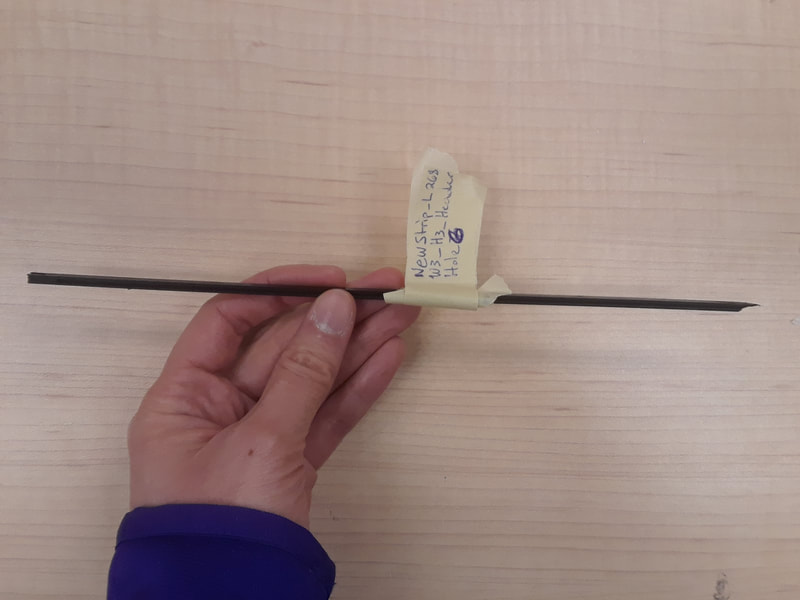

Files printed: NewStrip_L268_W3_H3_HeaderHole5.stl, NewStrip_L268_W3_H3_HeaderHole6.stl, NewStrip_L268_W3_H3_HeaderHole7.stl, and HeaderHole8.stl.

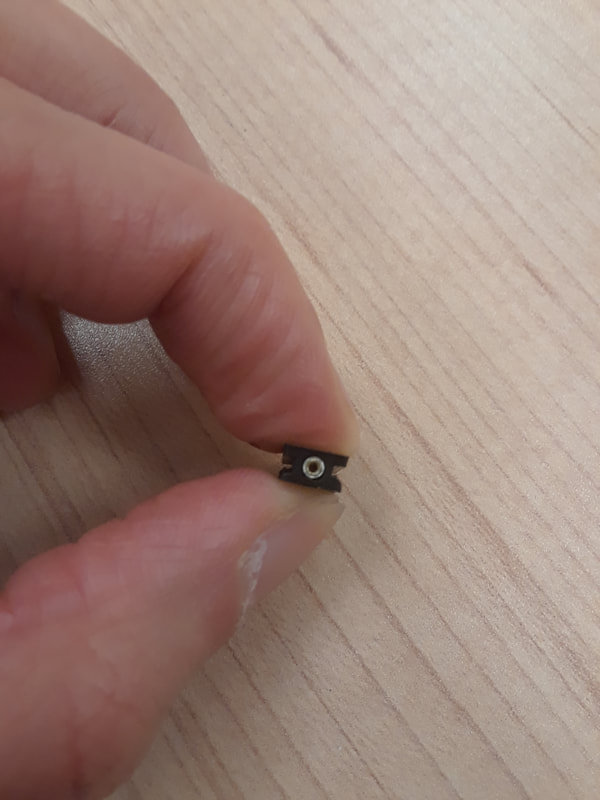

I discovered a few things about printing these very long, thin strips. When I modeled “…5” I added two holes on either side so the strip can slide into the fingerboard and be held there. “rails” I call them. I turned this print on its side so that it was laying on one of its rail sides. I also included half of a header hole for the next testing of that. I wanted to use dual extrusion with the second extruder printing the raft in PVA. However, when I selected raft instead of brim, the parameters of the build plate became smaller and way too small for the model. So I’m just going to stick with brim with support for now; all using single extrusion. When I pulled the print off, it curled way more than the last print. The rails also got stuck to the brim and I ripped some of them right off. It is damaged beyond usability, so I’m not going to test this one with the Arduino. When I tested it with the header, I did it in two extrusions. The first hole was a bit too small in diameter, and a bit too long in length. The second hole was a bit too big in diameter, and a bit too long too. When I modeled “…6”, the strip stayed the same, but the header hole changed a bit. I tried printing it flat (not on top of the rails), without a brim, and no supports. This time it stayed much firmer and didn’t bend so much. This time it stayed much firmer and didn’t bend so much. However, I accidentally snapped it at the end when I tried to take it off the plate. Going to see if I can print it on it’s side again because printing it flat this way will cause a problem later on. I’m not going to test this with the Arduino because it’s broken. For the hole, the first hole needs to be a bit bigger in diameter, and it’s just right in length. The second hole looks like the right diameter, but needs to be slightly shorter. When I modeled “…7” I printed it on it’s side again (rail side). I think I developed a technique to scrape it off the build plate with minimal damage to the print: by starting in the middle and scraping along the edges. By having the side that is exposed to the fingers, on the side instead of up, it caused periodic bumps along the surface. This is problematic. I will have to see if I can sand it down, or for the next print, print it on it’s other end, with supports. The only other way I can think of is make the bit around the header wider, don’t make it reach all the way down, and have a wider set of rails on the header piece. That way the whole thing is flat… maybe that is a better solution actually. I’ll test it with the Arduino another day because it’s getting late right now. For the hole, I didn’t account for the outer rim of the header being wider. That’s why it’s not fitting quite right. Otherwise it’s perfect and snug. Next time I print a hole, I’ll made it three extrusions again, 1 for the rim, the other for the body, the last for the pin. HeaderHole8: I left a little bit of the strip to see how it would look. I did the solution above, with making it a bit wider around the header hole than the rest of the strips, and add rails to it. The hole is a snug fit!!!!!! Now for testing the new strip with a “mock-up” fingerboard to test if the rails fit... Happy birthday to me!

File name: HalfHeaderHole2 I only got one print done before the nozzle clogged. I was trying to figure out the size of the header hole by printing just that one piece. Instead of printing the whole piece, I printed half of the diameter, so that way I can clearly see how it’s fitting from the outside. I did it with three extrusions to make the hole. I can now tell that the last extrusion is too narrow. The middle extrusion looks like the right diameter. The first extrusion is way too wide if the pin is without the casing. I accidentally scratched the print across the last hole in this picture. |

Welcome to the TRAVIS blog!If you would like to see a summary of my work, please click here. Archives

May 2022

Categories |

RSS Feed

RSS Feed