|

I also discovered that the printer made hole8 perfect with the regular pla, but when I used the conductive pla, the header didn’t quite fit, so I am testing again with the conductive… L.

Files: Hole9.stl, Hole10.stl, Hole9.2.stl.

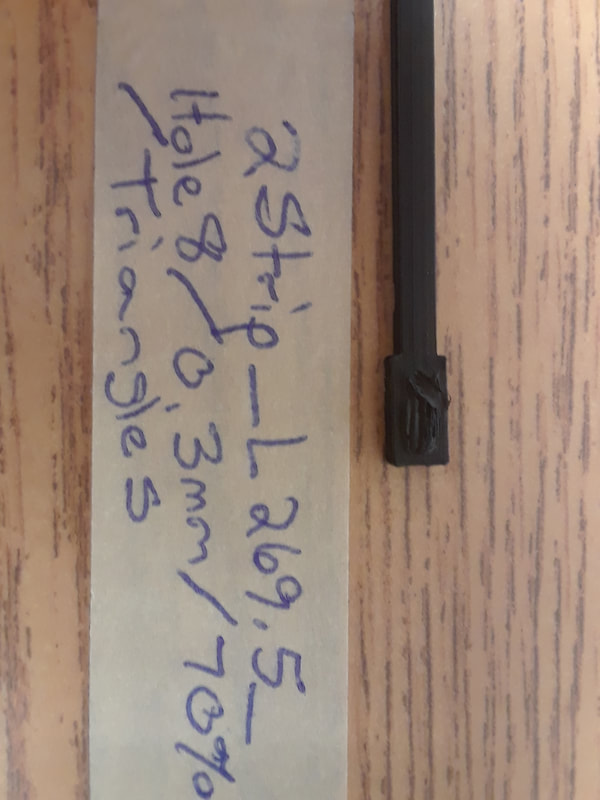

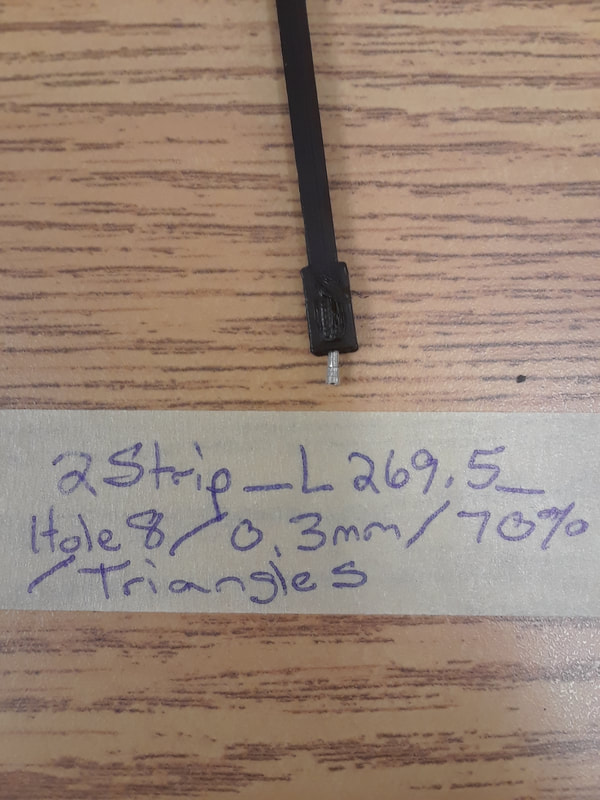

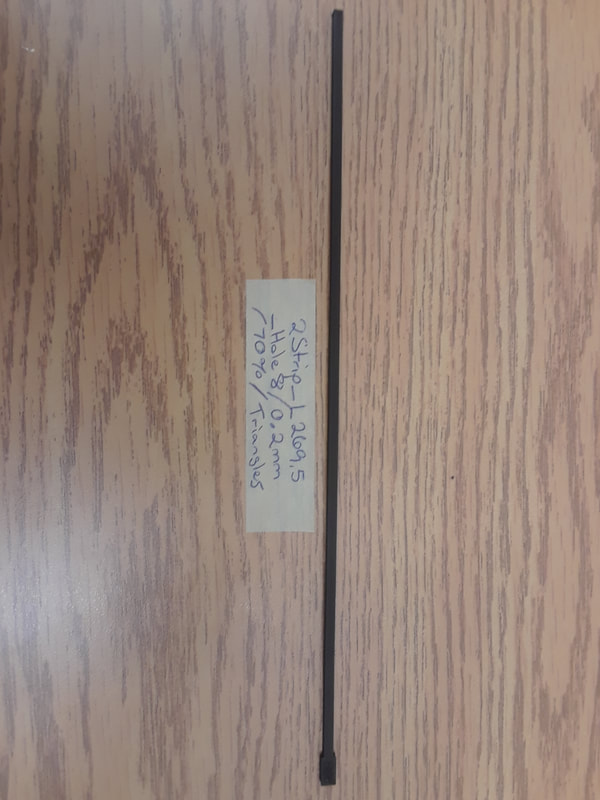

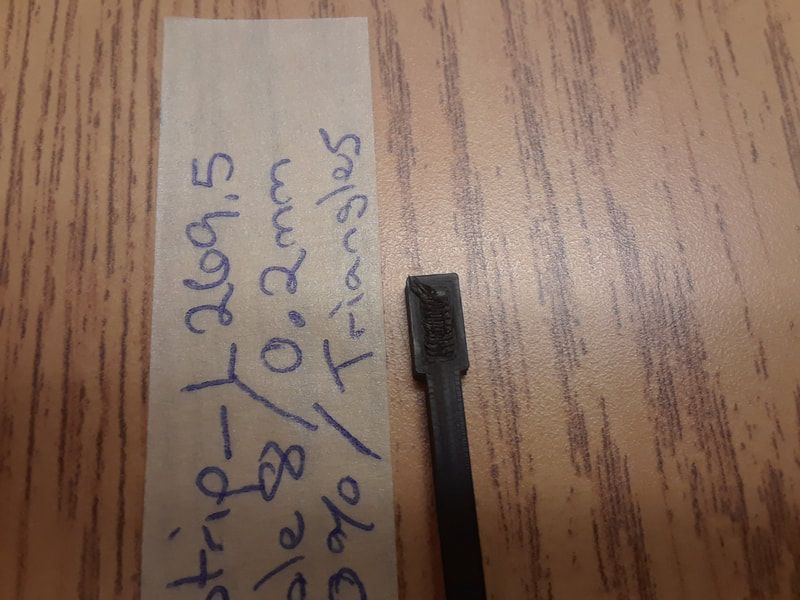

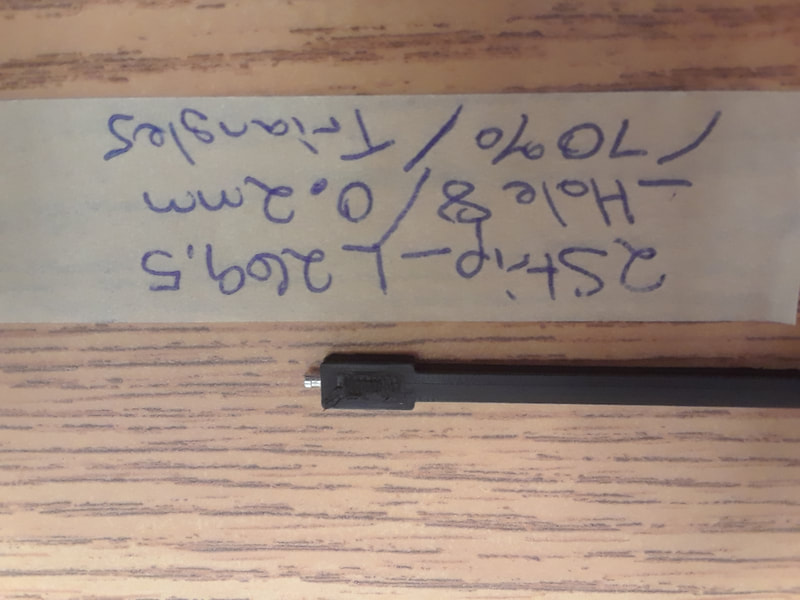

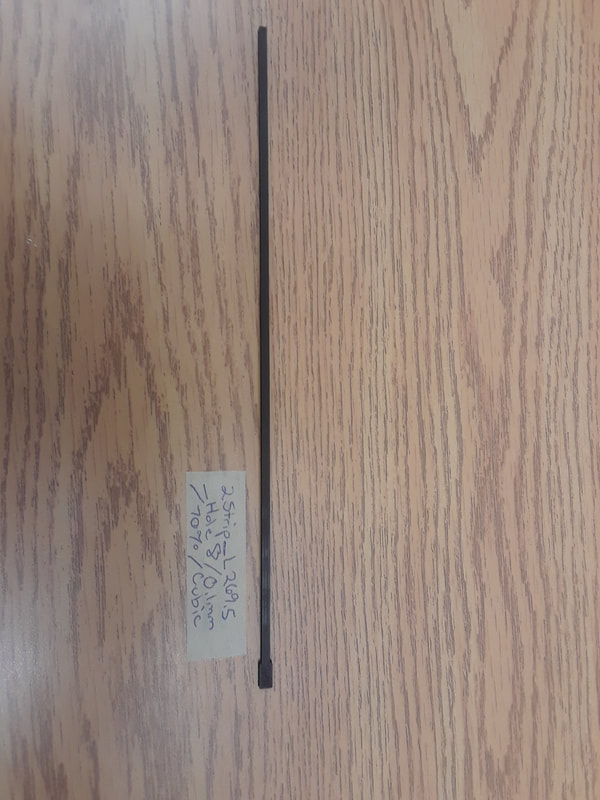

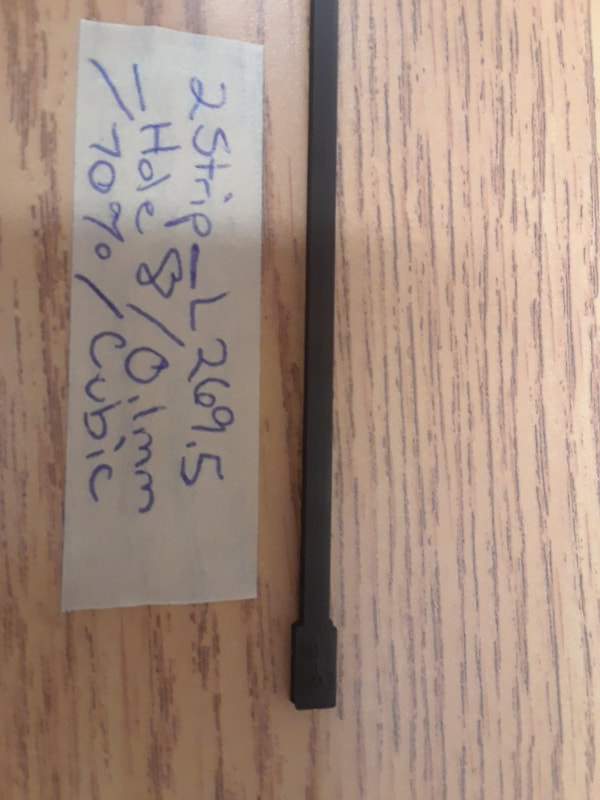

I decided to change up the printer settings to see if that changes the resistance of the same strip file. Infill density was always 70%. I tested different layer height thicknesses and different infill patterns. There was no significant differences with different patterns, but there was with different thicknesses. Test strip file: 2Strip_L269.5_Hole8.stl Strips: Layer Height: 0.1 mm. Infill Pattern: Triangles: Good fit with the test slot7. Good space at the very end to fit the needle. Took 44min to print. The header is not quite fitting in perfectly like it was with the regular PLA. It might have to do with the differences between conductive and regular? It’s not that bad though. I can still work with this. When I tested with the volt meter, the readings are much more stable than the last print that I tested with a volt meter for. When comparing with the other thicknesses, I think the 0.1mm is more stable than the others, but it’s really hard to tell. Multimeter Readings: 20MW : Close: 0 Mid: 0 End: 0.01 2MW : Close: 0.003 Mid: 0.007 End: 0.011 200KW Close: 4.0 Mid: 6.2 End: 11.2 20KW Close: 2.55 Mid: 6.1 End: 11.6 2kW: nothing Layer Height: 0.2mm. Pattern: Triangles. Takes 23 min to print. The top of the header piece is messed up and the header doesn’t fit in the slot. Better than the 0.3 though. Multimeter Readings: 20MW Close: 0 Mid: 0 End: 0 2MW Close: 0.003 Mid: 0.006 End: 0.009 200KW Close: 2.3 Mid: 6 End: 9.8 20KW Close: 3.38 Mid: 6.5 End: 8.66 2kW: 0L Layer Height: 0.3mm. Pattern: Triangles. Takes 16min to print. Much better than the 0.5mm infill. The top of the header piece is messed up and the header doesn’t fit in. This one fluctuates more than the other two. Multimeter Readings 20MW Close: 0 Mid: 0 End: 0 2MW Close: 0.004 Mid: 0.006 End: 0.01 200KW Close: 2.5 Mid: 9.5 End: 0L 20KW Close: 1.27 Mid: 5.8 End: 7.7 2kW: 0L Layer Height: 0.5mm. Pattern: Triangles. Takes 10min to print… don’t know why it’s so much different from the last one. It turned out absolute crap. The header looks messy at the top. I’m not even going to try to fit a header in there. It’s slightly smaller than the edges of slot7, so it is not flush with the top. Harder to get off of the build plate, so the header bent a bit, and won’t bend back. Not functional. Numbers are lower than the thinner thicknesses. The thicker the layer height, the worse the resistance gets. Multimeter Readings: 20MW : Close: 0 Mid: 0 End:0.01 2MW : Close: 0.002 Mid: 0.006 End: 0.02 200KW Close: 3.1 Mid: 4.7 End: 7.0 20KW Close: 1.64 Mid: 4.06 End: 6.82 2kW: 0L

0 Comments

Leave a Reply. |

Welcome to the TRAVIS blog!If you would like to see a summary of my work, please click here. Archives

May 2022

Categories |

RSS Feed

RSS Feed