|

I tested the strips after sanding them and they barely worked. I then took them out of the fingerboard and flipped them over to test the other side. The un-sanded side still worked fine. So, lesson learnt, to not sand the side of conductive PLA that needs to be conductive! I ended up re-printing all of my strips… again. I also sanded the sides of them so that they can fit into the slots, and that was fine, just as long as I didn’t sand the surface.

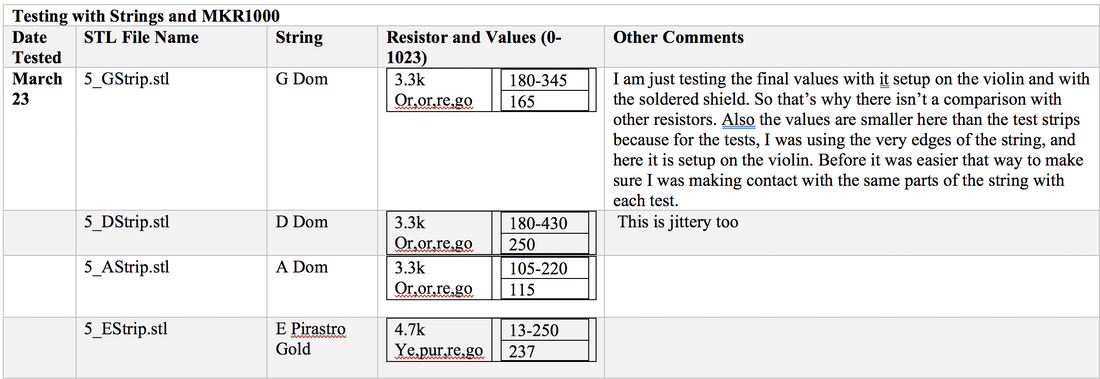

Here are the results for the re-printed strips: 5_GStrip.stl 20MW Close: 0 Mid: 0.01 End: 0.01 2MW Close: 0.002 Mid: 0.007 End: 0.011 200KW Close: 2.9 Mid: 6.4 End: 11.0 20KW Close: 2.19 Mid: 6.67 End: 10.89 2kW: 0L 5_DStrip.stl I noticed this one is a bit more jittery at the 20k setting at the far nut end. 20MW Close: 0 Mid: 0.01 End:0.01 2MW Close: 0.002 Mid: 0.009 End: 0.014 200KW Close: 1.7 Mid: 7.4 End: 12.5 20KW Close: 1.97 Mid: 8.25 End: 16.7 2kW: 0L 5_AStrip.stl 20MW Close: 0 Mid: 0 End: 0.01 2MW Close: 0.002 Mid: 0.01 End: 0.012 200KW Close: 1.8 Mid: 9.5 End: 13.4 20KW Close: 1.64 Mid: 6.63 End: 12.13 2kW: 0L 5_EStrip.stl 20k setting, starting at the middle is a bit jittery. Nut end isn’t too bad though. 20MW Close: 0 Mid: 0 End:0.01 2MW Close: 0.003 Mid: 0.006 End: 0.013 200KW Close: 3.0 Mid: 6.4 End: 11.2 20KW Close: 3.07 Mid: 7.55 End: 10.49 2kW: 0L

0 Comments

Leave a Reply. |

Welcome to the TRAVIS blog!If you would like to see a summary of my work, please click here. Archives

May 2022

Categories |

RSS Feed

RSS Feed